Your Sample. Our Purpose.

Automation tailored to your workflow – not the other way around!

Don't miss out on any more news!

Sample Preparation

Automation for GC, GC/MS, LC, LC/MS, or standalone

Thermal desorption

Flexible and robust systems for GC/MS

GC-Olfactometry

Detection of aromas, fragrances and off-odors

Personal contact

Direct, individual advice

News from GERSTEL

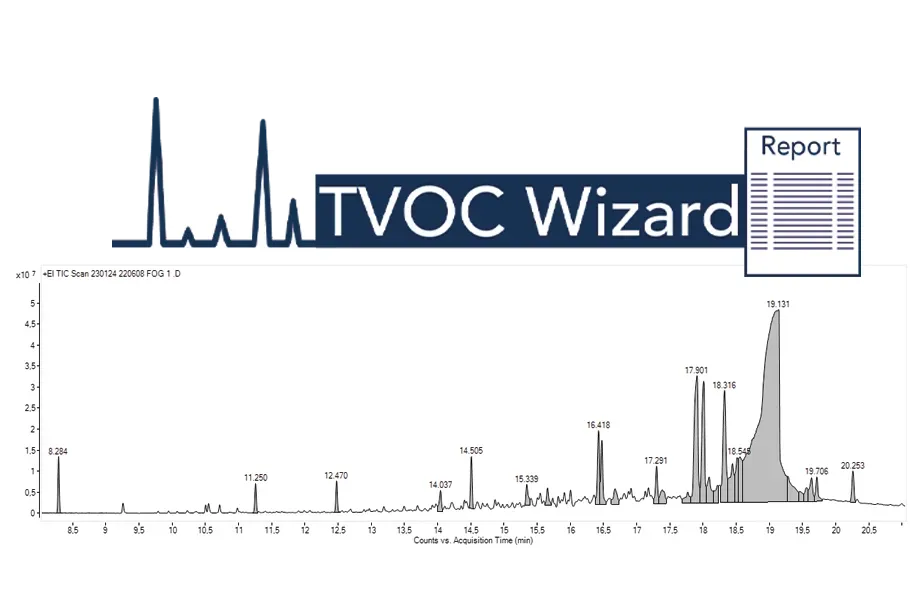

Automated TVOC Wizard Workflow:

Simplifying Data Processing

Utilisation of stir bar sorptive extraction for the analysis of biogenic amines in wines

Sensory Directed Analysis Workshops in Germany, China and Singapore

New AppNote: Sensory-Active Compounds in Cannabis

GERSTEL Applications

Background knowledge in a compact format: While our comprehensive AppNotes provide detailed analysis and technical guidance, the AppBriefs focus on presenting the most important insights and data in a clear, two-page format.

Experience GERSTEL

Our latest video